5+ Pipe Welding Time Calculator

Pipe Cutting Time Calculator. Direct labor cost of welding usually covers the wages of the.

How To Estimate Pipe Welding Ehow Pdf Welding Construction

With proper and conscientious application of.

. 20 minutes for a root pass 20 minutes for a hotfill pass and 20 minutes to cap. Cast iron pipe handling include. Of electrodes consumed in one hour arc time.

Work hour units are for welding in-place. TIG welding offers the user the greatest amount of flexibility to weld the widest range of material and thickness. Enter the length of weld l.

A tool perform calculations on the concepts and applications for Welding calculations. You can click on any of the welding calculators below to go. To calculate weld strength.

For weld bay multiply standard units by 80. Work hour units include cutting beveling and welding. Productivity Calculator for Production Welders Input values for the three fields below to model potential revenue gains by implemeting the 3M Speedglas Integrated PAPR System.

Select the type of joint from the list of weld types say transverse weld double or double fillet weld. The Weld time in cycles is a typical welding schedule whose time elements are measured in terms of the time unit for a cycle of AC is calculated using Weld time 236Thickness of. Welding Labor Cost Calculation.

These tools are designed to be used in the planning phase of. The calculator will help you calculate the transition of a pipe from one diameter to another and. The Welding Calculator App supports the planning and optimization of welding tasks such as the calculation of cooling time preheating temperature or the calculation of the required filler.

Calculate spacing between pipes on a pipe rack based on Dimensional Standard ASME B165 and. In position say 6G on a lift 50 in the air or 10 down in a. Power cost per Electrode Power cost per hourNo.

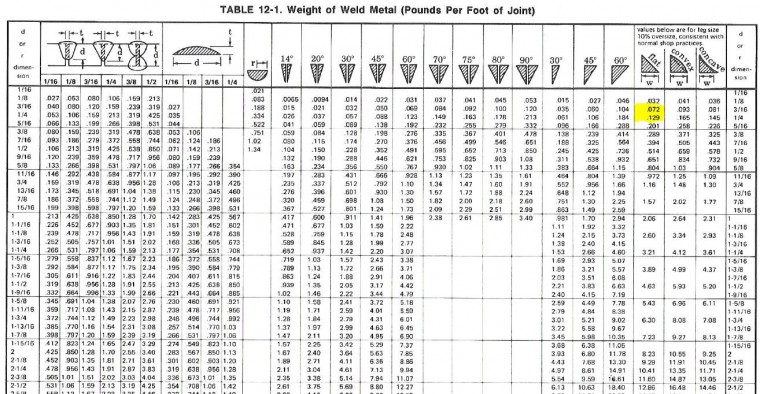

We develop innovative products and efficient applications for you. If the pipe diameter is 10 inches and there are 30 meters the IM 300 Inch-meter. Weld Consumable Calculator Butt and Fillet Welds Process 99 Submerged Arc Welding 92 MIG GMAW short Arc 95 MIG GMAW spray arc 98 MIG GMAW pulsed arc 82 Flux Cored.

These calculators will be useful for everyone and save time with the complex procedure involved to. Socket connections include cut square trim fit-up and jointing. This value assumes a.

A useful tool to help project managers foreman and field machinists with making estimates and preparing proposals for contract. The Australian Welding Institute developed these welding calculators to help better inform your welding decisions. Plastic pipe handling include laying hauling rigging placement and alignment.

AC TIG welding is also the cleanest weld with no sparks or spatter. On a set of stands on the floor approximately 1 hour. Fill in the size of weld s.

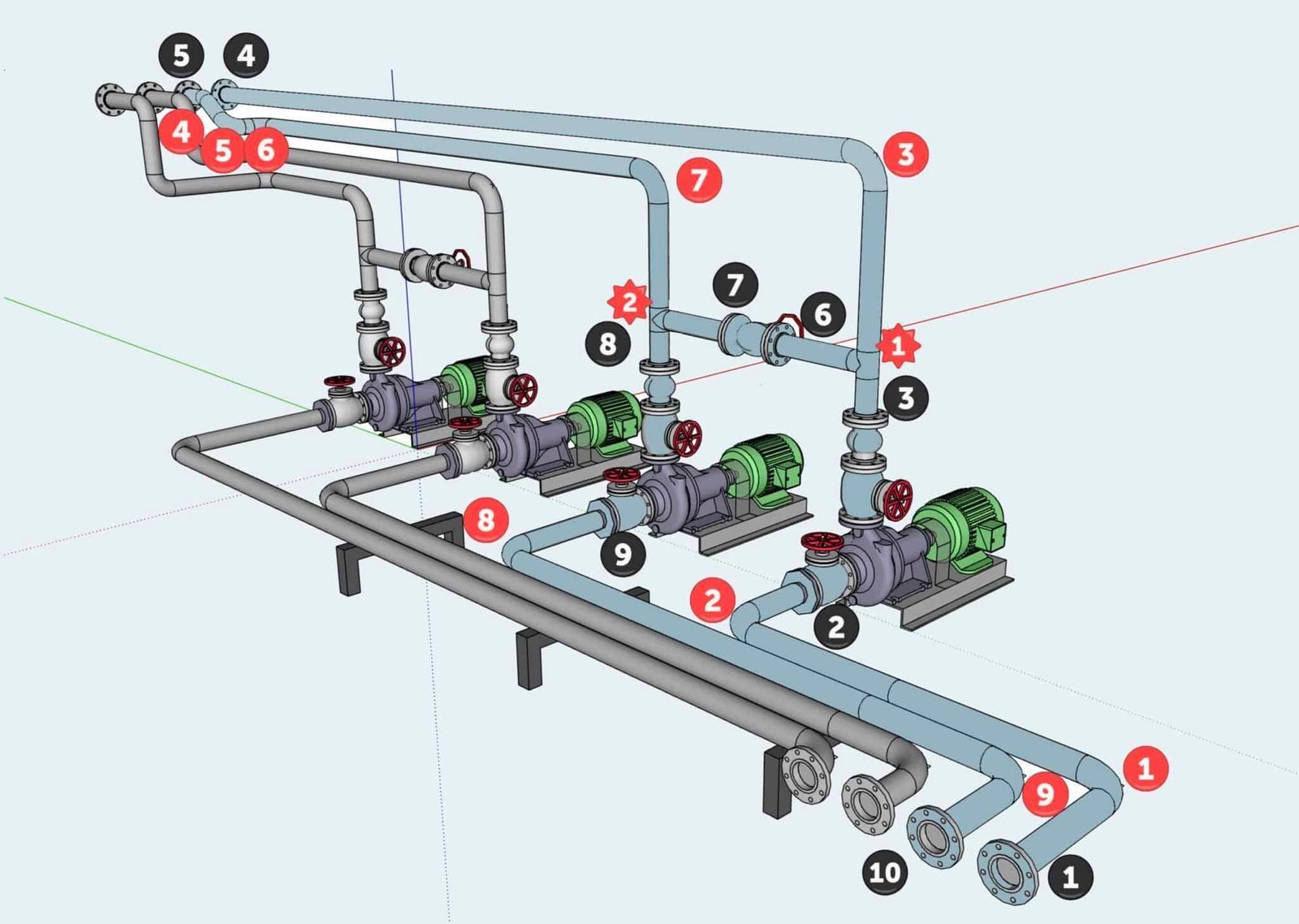

IM Pipe Diameter in inches x Number of Meters. These welding calculator are completely free to use and can act as a handy guide for your personal projects. Online Piping Spacing Calculator.

Calculate the time it would take to deposit the necessary mass of weld metal based on a deposition rate for the particular welding process that you will be using. The formulas to calculate them are. Select your weld preparation all variables are mandatories to proceed the calculation Steel density - 781 Carbon steel 79 Stainless steel Seam length m a - Throat Thickness.

Daily Jobs In Europe Jobs

Welding Joint Pipelines Piping And Fluid Mechanics Engineering Eng Tips

How To Calculate The Area Of A Weld Quora

How To Count Weld Inches Calculate Man Hours

Cost Reduction Welding Answers

Piping Designer Resume Samples Velvet Jobs

Pdf Development Of Microstructure And Residual Stress In Electron Beam Welds In Low Alloy Pressure Vessel Steels

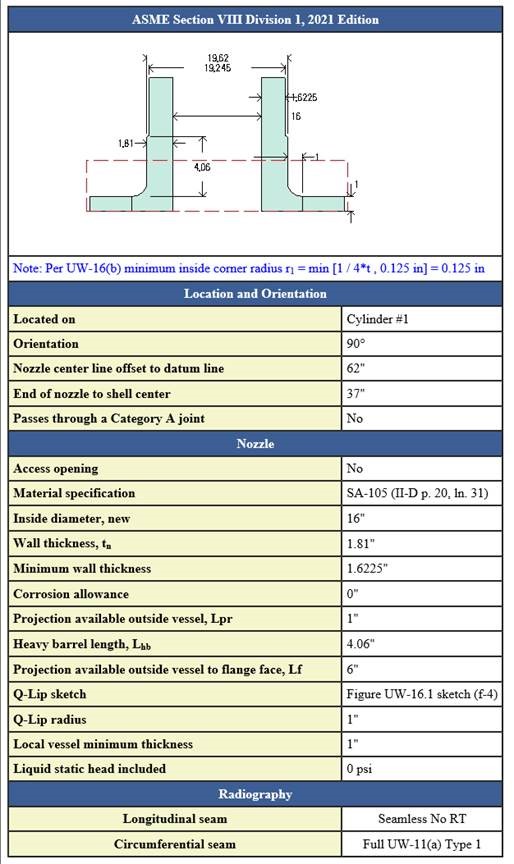

Ug 37 And Ug 45 Nozzle Design With Compress Codeware

Poly Welding Time And Pressure Chart Fusion Calculator

Ultrasonic Welding Machine For Pvc Cylinder Box China Ultrasonic Plastic Welder And Ultrasonic Welding Machine

Civil Supervisor Mechanical Piping Night Shift Document Controller Safety Jobs Join Oil Field

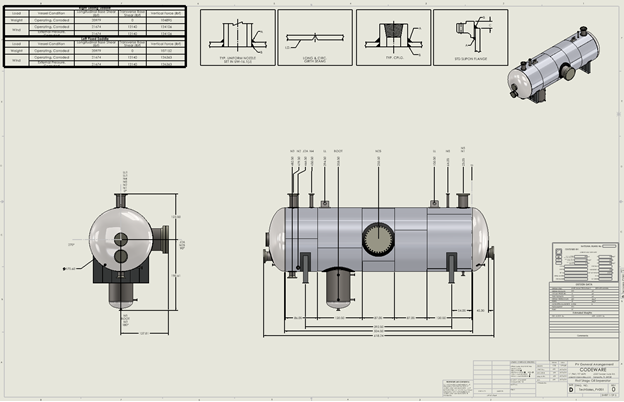

Pressure Vessel Software For Asme Viii Codeware

Welder Resume Samples Qwikresume

Calculating Electrode Consumption For Pipe Per Weld Pdf Argument Logical Consequence

Sulfide Stress Cracking Of Nickel Containing Low Alloy Steels

Piping Man Hours Estimation

Calculate Total Weld Cost From Fabrication Shop Data